Cu-W Alloy Applications

Cu-W alloy integrates advantages of tungsten and copper. Tungsten has high melting point and density, and conductive performance of copper is superior. Cu-W alloy has such advantages as homogeneous microstructure, high temperature resistance, high strength, arc ablation resistance, high density and appropriate thermal conduction, electric conduction. Cu-W alloy applications are as follows: Cu-W alloy is widely applied in military high temperature resistant materials, high voltage switch electrical alloy, EDM electrode and microelectronic materials. Cu-W alloy is also widely used in aerospace, aviation, electronics, electric power, metallurgy, machinery, sports equipment industry as parts and components.

1.Cu-W alloy application in military high temperature resistant materials:

Cu-W alloy is used in missile, nozzle of rocket engine, gas rudder, air vane and nose cone.

2.Cu-W alloy application in high voltage switch electrical alloy:

Cu-W alloy is widely used in high voltage switch circuit breaker high-voltage vacuum load switch and lightning arrester. High voltage vacuum switch has the advantages of small volume, easy maintenance, wide application and it can be used in moist, flammable and explosive and corrosive environments.

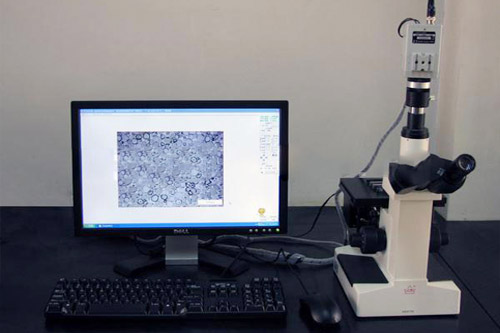

3.Cu-W alloy application in EDM electrode:

Cu-W alloy electrode has the advantages of high temperature resistance, high strength, high temperature arc ablation resistance, and good conductive performance and thermal conductivity. Cu-W alloy electrode includes EDM electrode, welding electrode and high-voltage discharge electrode.

4.Cu-W alloy application in microelectronic materials:

Cu-W electronic packaging has the property of low expansion property, high heat conductivity. Its thermal expansion coefficient and thermal conductivity properties can be adjusted by the

tungsten and copper composition, thus giving Cu-W alloy a wide range of application.

Zhengzhou Sanhui Co., Ltd also provides heavy alloy products and tungsten molybdenum alloy products.

If you interested in our products, please feel free to contact us.

1.Cu-W alloy application in military high temperature resistant materials:

Cu-W alloy is used in missile, nozzle of rocket engine, gas rudder, air vane and nose cone.

2.Cu-W alloy application in high voltage switch electrical alloy:

Cu-W alloy is widely used in high voltage switch circuit breaker high-voltage vacuum load switch and lightning arrester. High voltage vacuum switch has the advantages of small volume, easy maintenance, wide application and it can be used in moist, flammable and explosive and corrosive environments.

3.Cu-W alloy application in EDM electrode:

Cu-W alloy electrode has the advantages of high temperature resistance, high strength, high temperature arc ablation resistance, and good conductive performance and thermal conductivity. Cu-W alloy electrode includes EDM electrode, welding electrode and high-voltage discharge electrode.

4.Cu-W alloy application in microelectronic materials:

Cu-W electronic packaging has the property of low expansion property, high heat conductivity. Its thermal expansion coefficient and thermal conductivity properties can be adjusted by the

tungsten and copper composition, thus giving Cu-W alloy a wide range of application.

Zhengzhou Sanhui Co., Ltd also provides heavy alloy products and tungsten molybdenum alloy products.

If you interested in our products, please feel free to contact us.

Prev:上一篇:Titanium Discovery and Development

Next:下一篇:Basic Knowledge about Nickel